Abstract

Oligoisoprene macromonomer, which bears a terminal vinyl group, was prepared by the metathesis degradation of high-molecular-weight polyisoprene with ethylene for coordination polymerization. The ethenolysis of polyisoprene using the 2nd-generation Grubbs catalyst (G2) at ambient pressure gave heterotelechelic (α-vinyl-ω-vinylidene) oligoisoprene, keeping the stereoregularity in high yield, whereas the 1st generation Grubbs catalyst was immediately deactivated. In such metathesis degradation, an intramolecular side reaction giving cyclic oligomers may be competitive, but ethenolysis proceeded with high selectivity, probably because of the least steric effect of ethylene. The ethenolysis is also applicable for the degradation of natural rubber-derived polyisoprene, although the catalytic activity decreased. The prepared oligoisoprene macromonomer was successfully copolymerized with ethylene using a phenoxyimine-ligated titanium catalyst, and the reactivity of the macromonomer was almost the same as that of 1-hexadecene. The oligoisoprene-grafted polyethylene showed a typical stress‒strain curve, of which the tensile modulus and yielding stress are comparable to those of linear low-density polyethylene.

Similar content being viewed by others

Introduction

Olefin metathesis is an essential fundamental reaction in polymer chemistry that is applied to ring-opening metathesis polymerization (ROMP) and acyclic diene metathesis polymerization (ADMET) [1,2,3,4]. The design of alkylidene catalyst enables the promotion of ROMP in a living manner and/or a stereospecific manner, which can give various shapes of polymers, such as bottlebrush polymers, cyclic olefin polymers, and other block copolymers. Moreover, the cross-metathesis reaction between different polymers can be an efficient method to reach multiblock copolymers.

The metathesis reaction is also effective for the degradation of polymers possessing C=C double bonds in the main chain. In particular, metathesis degradations of polybutadiene and polyisoprene (PIP), including natural rubber, have vigorously been investigated, aspiring to the upcycling of rubber materials. In view of the degradation process, the low operation temperature of metathesis is advantageous over pyrolysis and anionic degradation [5, 6].

Degradation using internal olefins having α,ω-bifunctinal groups, giving telechelic oligomers, is one of the possible candidates for the efficient transformation of polydienes. For example, chain scission reagents possessing functional groups [7,8,9] or initiators of controlled radical polymerizations [10] and plant-derived reagents [11] have been applied for various applications. In these degradations, the molecular weight of the polymer is controlled by the amount of chain scission reagents. Ethylene is also a possible chain scission reagent, giving vinyl-terminated telechelic polymers [12]. The obtained oligomers are equivalent to vinyl hydrocarbon monomers suitable for coordination olefin polymerization. In polyolefin chemistry, the introduction of saturated long-chain alkyl branches by copolymerization is important because it often improves the mechanical properties of polyethylene and polypropylene. Vinyl-terminated oligodienes can be an alternative to α-olefins if they are easily accessible from inexpensive feedstocks such as waste rubber. Previously, oligoterpenes [13], trans-1,4 PIP [14], or partially hydrogenated PIP [15] were successfully degraded to oligomers by metathesis with ethylene, although the oligomer has not been fully characterized in some examples.

Intermolecular metathesis degradation using chain scission reagents can be competitive with intramolecular degradation. Metathesis degradation of polydienes without a chain scission reagent often gives a mixture of small oligomers because of the back-biting reaction. Such degradation proceeds even for crosslinked polydiene materials [16]. For cross-metathesis to synthesize block copolymers or macromonomer synthesis, the prevention of overdegradation would be important to achieve a high yield [17, 18]. On the other hand, for ultrahigh-molecular-weight polydienes, pretreatment to reduce the molecular weight is sometimes important for the controlled synthesis of telechelic polydienes and polydiene-based block copolymers [19, 20].

The metathesis degradation behavior of PB has recently been precisely investigated. The most thermodynamically stable product is a cyclic trimer consisting of a C12 skeleton, and larger C16-C44 oligomers are kinetically obtained by the degradation of cis-1,4 polybutadiene using ruthenium catalysts [21]. The ratio of C12 and larger oligomers can be controlled by catalyst design, and indenylidene ruthenium catalysts are more effective for obtaining macrocyclic oligomers. On the other hand, the metathesis degradation behavior of PIP has not been investigated, although the thermodynamic stability of dimers and trimers derived from PIP has previously been computationally discussed [22].

In this context, we were interested in the preparation of a telechelic PIP macromonomer for vinyl polymerization using ethenolysis of cis-1,4 PIP. Telechelic oligomers with a molecular weight of several thousand have been previously reported using various 1-alkenes and stilbenes [23], and our work aims to synthesize much shorter oligomers for macromonomers. PIP-based macromonomers for graft copolymerization with ethylene and propylene have previously been prepared by anionic oligomerization, which gave polyisoprene with 69% cis-1,4, 23% trans-1,4, and 7% 3,4 units [24]. The ethenolysis of high cis-1,4 polyisoprene should give more stereoregular oligomers. The competitive metathesis degradation behavior of synthetic PIP and natural rubber without chain scission reagent was also investigated for comparison. Additionally, we performed the copolymerization of ethylene with the obtained oligoisoprene and successfully obtained oligoisoprene-grafted polyethylene.

Experimental procedure

General

All manipulations were performed under an atmosphere of nitrogen using standard Schlenk line techniques. Dry toluene and dichloromethane (Kanto Chemical Co. Inc.) were purified using an organic solvent purifier (Glass Contour) or dried on Molecular Sieves 3 A before use. Ethylene gas (Sumitomo Seika Co. Ltd.) was used by passing the gas stream through Nikka Seiko GC-RP and DC-A4 columns prior to use to remove trace amounts of O2 and water. Synthetic polyisoprene (1,4- content = 95%, Mn = 13000, Ð = 2.9) and natural rubber (1,4- content =99%, Mn = 8900, Ð = 3.7) were purchased from Aldrich and used after reprecipitating the polymer solution in THF into excess methanol and drying under vacuum. Half-titanocene Ti1 and phenoxyimine-ligated titanium complex Ti2 were synthesized according to the literature [25, 26]. Other materials were used as purchased.

1H NMR spectra were recorded on a Varian 500 NMR or a JEOL Lambda500 spectrometer. The obtained spectra were referenced to the signals of residual traces of the partially protonated solvent [1H: δH (CHCl3) = 7.26 ppm, δH (C2DHCl4) = 5.91 ppm] or solvent [13C: δC (CDCl3) =77.1 ppm, δD (C2D2Cl4) = 74.7 ppm]. GC‒MS analysis was performed on a Shimadzu GCMS-QP2010SE spectrometer equipped with a Restek Rxi-5Sil MS column (0.25 mm×30 m). The molecular weight of the obtained polymer was determined by GPC on a TOSOH HLC-8320 (T = 40 °C; eluent: THF) or a Malvern GPC-350HT (T = 130 °C, eluent: o-dichlorobenzene) chromatograph calibrated with polystyrene standards. The concentration of polymers in the injected solutions was ca. 3 mg/mL, and the injection volume was 0.2 mL. DSC measurements were performed on a SHIMADZU DSC-60 system with a temperature elevation rate of 10 °C min−1. A polymer sheet with a thickness of 1 mm was fabricated by pressing the polymer at 150 °C and 20 MPa for 5 min using a pair of stainless plates with Teflon spacers. A dumbbell-shaped specimen with a 12 mm × 2 mm size was cut from the film and used for the mechanical test. Tensile tests were performed using an A&D RTC-1210A tensile tester at 25 °C and a constant crosshead speed of 10 mm min–1.

Ethenolysis of cis-1,4 PIP

As a representative procedure, run 10 in Table 1 is described. In a 100-mL two-necked flask, synthetic PIP (680 mg, 10.0 mmol) was charged and dissolved in CH2Cl2 (26.5 mL). Nitrogen in the headspace of the flask was evacuated under vacuum, and ethylene gas was backfilled until saturation at room temperature. A solution of 2nd generation Grubbs catalyst (G2, 10 mg, 12 µmol) in CH2Cl2 (1 mL) was added to the solution to initiate ethenolysis. After 15 h, the reaction was terminated by adding MeOH, and the solution was filtered through silica gel to remove the ruthenium catalyst. Removal of the solvent under vacuum conditions gave 547 mg (80%) of telechelic oligomer as a yellowish oil.

Metathesis degradation of cis-1,4 PIP without chain scission reagent

In a 100-mL two-necked flask, PIP (200 mg, 3.0 mmol) was charged and dissolved in CH2Cl2 (9 mL). A solution of G2 (4.2 mg, 5 µmol) in CH2Cl2 (1 mL) was added to the solution to start degradation. An aliquot of solution (0.2 mL) was taken after certain reaction times (1 and 3 hours) and poured into THF containing ethyl vinyl ether to terminate the metathesis reaction. The resulting solution was analyzed by GPC. After 16 h, the reaction was quenched by ethyl vinyl ether, and the solution was concentrated. A total of 158 mg (79%) of the oligomer was recovered as a brown oil.

Copolymerization of ethylene and telechelic oligoisoprene

In a 100-ml 2-necked glass reactor, telechelic oligoisoprene macromonomer (360 mg, Mn = 720, 0.50 mmol as vinyl monomer) was charged and dissolved in 13 mL of toluene. Then, a solution of MAO in toluene (2.8 M, 1.0 mL, 2.8 mmol) was added and stirred for 1 min. Nitrogen in the headspace of the flask was evacuated under vacuum, and ethylene gas was backfilled until saturation at room temperature. The polymerization was started by adding a solution of catalyst Ti2 (7.3 mg, 10 µmol) in toluene (1.0 mL) under ethylene flow. After 10 minutes, polyethylene started to precipitate, and the polymerization was terminated by pouring the resulting solution into acidic methanol (200 mL) containing concentrated hydrochloric acid (4 mL). The precipitated polymer was collected by filtration, washed several times with CH2Cl2, and dried under vacuum for 6 h. A total of 213 mg of colorless semicrystalline polymer was obtained.

Results and discussion

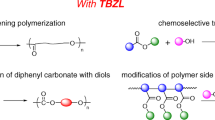

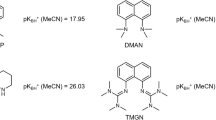

Ethenolysis using Grubbs’s ruthenium alkylidene catalyst was attempted for commercially available synthetic PIP (Mn = 13000, Ɖ = 2.9, cis-1,4 content = 86%) under pressurized conditions (Scheme 1). The 2nd generation Grubbs catalyst (G2), which was effective for metathesis degradation using other chain scission reagents, gave a good result for the ethenolysis of synthetic PIP (Table 1). The 1st generation Grubbs catalyst (G1) gave an almost quantitative recovery of the starting polymer, probably because of the decomposition of the catalyst. Bubbling ethylene into a G1 solution in toluene immediately turns the catalyst solution color purple to greenish brown, indicating that the generated ruthenium ethylidene complex is very unstable.

At any catalyst loading per C=C double bond in the polymer, a decrease in molecular weight was observed in one hour (run 1–4). The resulting oligomer was roughly fractionated by precipitating a relatively high-molecular-weight oligomer into excess methanol. The oligomer was not quantitatively recovered, probably because a very small amount of product, such as monomers and dimers, was evaporated when drying the methanol-soluble fraction. Indeed, GC‒MS analysis of the product solution showed the presence of a compound with a mass-to-charge ratio (m/z) of 81, indicating the formation of 2-methyl-1,5-hexadiene via ethenolysis of two C=C double bonds located next to each other.

The 1H NMR spectrum of relatively low molecular weight fractions newly showed two signals at 5.0 and 4.7 ppm, which can be assigned to a pair of vinyl and vinylidene protons at the chain end in a 1:1 integral ratio (Fig. 1). These pairs of terminal olefins are also observed in the 13C NMR spectrum at 145.8, 138.6, 114.4, and 109.8 ppm as a new series of signals, clearly indicating that heterotelechelic oligoisoprene was successfully obtained (Supplementary Fig. S5 in the supporting information). The APCI-MS spectrum of the resulting polymer also showed a series of peaks with multiple m/z values of 68 and residual 28 (C2H4), indicating the formation of a heterotelechelic polymer via ethenolysis (Supplementary Fig. S6 in the supporting information).

1H NMR spectrum of heterotelechelic oligoisoprene obtained in Table 1, run 2 (500 MHz, in CDCl3)

The stereoregularity of the resulting oligoisoprene calculated from 1H and 13C NMR was cis-1,4:trans-1,4:3,4 = 86:9:5, which was the same as the original structure, indicating almost no isomerization reaction during the metathesis degradation. The regulated structure was in contrast with the WCl6/SnMe4 catalyst system, giving a mixture of saturated hydrocarbon oligomers [27]. In this case, the C=C double bond of the oligomer may be consumed by the in situ-generated cationic metal species, frequently seen in the cationic polymerization of dienes [28].

Prolonging the reaction time decreases the molecular weight of telechelic PIP to below 1000 after reacting for 24 h (runs 5–7). Raising the reaction temperature above 50 °C gave almost the same result in a short time (runs 8 and 9). Finally, the reaction at ambient pressure gave the best result in terms of yield, indicating that avoiding overdegradation is the key to the selective formation of oligomers (run 10). This ethenolysis is also effective for the degradation of PIP isolated from natural rubber, although the reaction is slower than the synthetic PIP because a small amount of impurity partially deactivated the catalyst (run 11).

In these resulting oligomers, the calculated molecular weights from the ratio of the alkenyl main chain and vinylidene protons in the 1H NMR spectra showed almost the same or slightly less value than those from GPC calibrated with polystyrene standards, which is nicely explained by the Mark-Houwink coefficients of these polymers [29]. This result shows that unreacted PIP or cyclic oligomers derived from back-biting are scarcely obtained. The molecular weight dependence on the glass transition temperatures of the obtained oligomers followed the Flory-Fox equation (Fig. 2) [30]. Considering that these oligomers are used as a macromonomer, controlling the glass transition temperature would be important for controlling the physical properties of the final copolymer.

Metathesis degradation in the absence of a chain scission reagent was also investigated (Scheme 2). The reaction with G2 led to the degradation of PIP to give a methanol-soluble fraction with a number-average molecular weight (Mn) of 820 after 15 h, which is comparable to the results of ethenolysis. The product distribution cannot be determined because no significant peak was detected by GC‒MS analysis, and 1H NMR typically showed signals for cis-1,4-rich polyisoprene without detectable chain ends. A reaction using a mixture of PIP with different molecular weights was investigated to reveal the detailed mechanism of metathesis degradation (Fig. 3). The transition of GPC traces showed that the bimodal mixture once became multimodal and converged to a single-modal, low-molecular-weight distribution. These results indicated that both intermolecular back-biting and intramolecular cross-metathesis reactions occurred during degradation, finally giving macrocyclic oligoisoprene. In the ethenolysis condition, such metathesis equilibrium may also be present, but the reaction with ethylene more selectively occurs because of the steric effect. No degradation occurred with G1 under the same conditions, which promoted the degradation of polybutadiene and selectively gave oligobutadiene macrocycle [21], probably because of the low reactivity toward trisubstituted olefins. Here, deactivation of the catalyst did not appear to occur because the purple color of the solution did not change after the reaction.

The synthesized oligoisoprene was applied as a macromonomer of coordination olefin polymerization. First, we attempted homopolymerization of the oligoisoprene using the half-titanocene catalyst Ti1, which promoted various homopolymerization and copolymerizations of α-olefins [31], but the macromonomer was recovered after the reaction (Scheme 3).

Then, we investigated the copolymerization of oligoisoprene with ethylene using the phenoxyimine-ligated titanium catalyst Ti2, which was effective for the copolymerization of ethylene and various α-olefins [32] (Scheme 4). Copolymerization at ambient pressure and temperature successfully gave oligoisoprene-grafted polyethylene (Table 2, run 2). The unreacted macromonomer can be removed by washing the polymer several times with CH2Cl2. The purified graft copolymer was completely soluble in o-dichlorobenzene or tetrachloroethane at high temperatures. A comparison of GPC traces between the obtained copolymer and oligoisoprene macromonomer clearly showed that residual macromonomer was completely removed from the copolymer (Fig. 4). Moreover, in the 1H NMR spectrum of the copolymer, signals of cis-1,4-rich polyisoprene and polyethylene were observed (Fig. 5), and signals of terminal vinyl groups in addition to the 1,2-sequence were not observed. The spectrum showed that the C=C double bonds in the oligoisoprene main chain were not consumed during the polymerization, whereas terminal vinyl groups reacted by copolymerization. Assuming that the number-average molecular weight of the macromonomer was 720, which was calculated from the 1H NMR spectrum of the macromonomer, the incorporation ratio of the macromonomer was 1.1 mol%. This value implied that the macromonomer occupied 20.6 wt% of the graft copolymer. The graft copolymer showed a lower melting temperature (Tm) than the homopolyethylene obtained by the same catalyst system (Table 2, run 1), but it was high for its composition, probably because polyethylene and grafting chains formed microphase-separated structures. Neither the glass transition temperature (Tg) for polyethylene nor oligoisoprene was observed. The copolymerization of ethylene and polyisoprene macromonomer showed lower catalytic activity than that of ethylene and 1-hexadecene, but the incorporation ratios of these comonomers were almost the same (run 3). The oligoisoprene obtained by metathesis degradation without chain scission reagent did not copolymerize with ethylene (run 4). In this polymerization, the activity was almost the same as that of ethylene homopolymerization. The difference in catalytic activity in runs 2 and 4 can be explained as follows: internal C=C double bonds in the macromonomer could only intercept the coordination of other olefin monomers when the macromonomer was incorporated into the propagating polymer chain, and its C=C double bonds were located close to the metal center.

GPC traces of PIP-grafted polyethylene obtained in Table 2, run 2 and the original macromonomer (3.8 mg/mL)

1H NMR spectrum of PIP-grafted polyethylene obtained in Table 2, run 2 (in C2D2Cl4, 500 MHz, 130 °C)

The obtained PIP-grafted polyethylene can be molded into a specimen with a thickness of 1 mm by pressing the polymer at 150 °C. The copolymer showed a typical stress‒strain curve with a clear yielding region (Fig. 6). The tensile modulus (115 ± 18 MPa) and yielding stress (10.0 ± 0.7 MPa) showed a comparable value with the commercially available linear low-density polyethylene.

A representative stress‒strain curve of PIP-grafted polyethylene obtained in Table 2, run 2

Conclusion

The preparation of heterotelechelic oligoisoprene bearing vinyl and vinylidene chain ends was successfully achieved by the ethenolysis of polyisoprene using a G2 catalyst. The molecular weight of the resulting oligomer can be controlled by the reaction time and temperature. This method also applies to natural rubber-based polyisoprene, although the catalytic activity was decreased because of impurities. At the current stage, a highly cis-1,4-rich polyisoprene-based macromonomer can only be accessible with our method. During ethenolysis, intramolecular metathesis equilibrium and intermolecular back-biting reactions may also exist. However, selectivity for ethenolysis would be very high considering the slight difference in molecular weight determined by GPC and NMR. The obtained oligoisoprene can be applied as a macromonomer for coordination olefin polymerization. Copolymerization with ethylene successfully gave oligoisoprene-branched polyethylene with a high melting point.

References

Bielawski CW, Grubbs RH. Living ring-opening metathesis polymerization. Prog Polym Sci. 2007;32:1–29.

Atallah P, Wagener KB, Schulz MD. ADMET: the future revealed. Macromolecules. 2013;46:4735–41.

Schrock RR. Synthesis of stereoregular polymers through ring-openingmetathesis polymerization. Acc Chem Res. 2014;47:2457–66.

Liu P, Ai C. Olefin metathesis reaction in rubber chemistry and industry and beyond. Ind Eng Chem Res. 2018;57:3807–20.

Han W, Han D, Chen H. Pyrolysis of waste tires: a review. Polymers. 2023;15:1604.

Tang J, Xie T, Yuan Y, Hua J, Zhuang T, Luo Y, et al. Degradation of polydienes induced by alkyllithium: characterization and reaction mechanism. Macromolecules. 2021;54:1147–58.

Solanky SS, Campistron I, Laguerre A, Pilard JF. Metathetic selective degradation of polyisoprene: low-molecular-weight telechelic oligomer obtained from both synthetic and natural rubber. Macromol Chem Phys. 2005;206:1057–63.

Michel X, Fouquay S, Michaud G, Simon F, Brusson JM, Capentier JF, et al. Simple access to alkoxysilyl telechelic polyolefins from ruthenium-catalyzed cross-metathesis depolymerization of polydienes. Eur Polym J. 2017;96:403–13.

Jambou C, Pilard JF, Gaumont AC, Dez I. Telechelic phosphonated rubber from metathetic depolymerization of polydienes and of waste tires. Eur Polym J. 2023;185:111805.

Saetung N, Campistron I, Pascual S, Pilard JF, Fontaine L. One-pot synthesis of natural rubber-based telechelic cis-1,4-polyisoprenes and their use to prepare block copolymers by RAFT polymerization. Macromolecules. 2011;44:784–94.

Gutiérrez S, Tlenkopatchev MZ. Metathesis of renewable products: degradation of natural rubber via cross-metathesis with β-pinene using Ru-alkylidene catalysts. Polym Bull. 2011;66:1029–38.

Bidange J, Fischmeister C, Bruneau C. Ethenolysis: a green catalytic tool to cleave carbon–carbon double bonds. Eur J Inorg Chem. 2016;22:12226–44.

Wolf S, Plenio H. On the ethenolysis of natural rubber and squalene. Green Chem. 2011;13:2008–12.

Ouardad S, Peruch F. Metathetic degradation of trans-1,4-polyisoprene with ruthenium catalysts. Polym. Degrad. Stab. 2014;99:249–53.

Shiono T, Naga N, Soga K. Metathesis degradation of partially hydrogenated cis-1,4-polybutadiene with ethylene. Kobunshi Ronbunshu. 1993;50:873–80.

Herman JA, Seazzu ME, Hughes LG, Wheeler DR, Washburn CM, Jones BH. Depolymerization of cross-linked polybutadiene networks in situ using latent alkene metathesis. ACS Appl Polym Mater. 2019;1:2177–88.

Abbas M, Neubauer M, Slugovc C. Converting natural rubber waste into ring-opening metathesis polymers with oligo-1,4-cis-isoprene sidechains. Polym Chem. 2018;9:1763–6.

Shoda Y, Aoki D, Tsunoda K, Otsuka H. Polybutadiene rubbers with urethane linkages prepared by a dynamic covalent approach for tire applications. Polymer. 2020;202:122700.

Ying W, Pan W, Gan Q, Jia X, Grassi A, Gong D. Preparation and property investigation of chain end functionalized cis-1,4 polybutadienes via de-polymerization and cross metathesis of cis-1,4 polybutadienes. Polym Chem. 2019;10:3525–34.

Zhang L, Quan Y, Wang H, Han H, Liao X, Sun R, et al. Tandem metathesis depolymerization and cyclopolymerization toward flexible–rigid block copolymers with unique damping properties. Polym Chem. 2022;13:3670–80.

Dewaele A, Renders T, Yu B, Verpoort F, Sels BF. Depolymerization of 1,4-polybutadiene by metathesis: high yield of large macrocyclic oligo(butadiene)s by ligand selectivity control. Cat Sci Technol. 2016;6:7708–17.

Gutierras S, Vargas SM, Tlenkopatchev MA. Computational study of metathesis degradation of rubber. distributions of products for the ethenolysis of 1,4-polyisoprene. Polym Degrad Stab. 2004;83:149–56.

Hu G, Lin S, Zhao B, Pan Q. Synthesis and characterization of natural rubber-based telechelic oligomers via olefin metathesis. J. Appl. Polym. Sci. 2021;138:e49899.

Endo K, Senoo K, Takakura Y. Synthesis of polyisoprene macromonomer having terminal vinyl group and copolymerization of the macromonomer with ethylene and propylene. Eur. Polym. J. 1999;35:1413–7.

Mitani M, Furuyama R, Mohri J, Saito J, Ishii S, Terao H, et al. Syndiospecific living propylene polymerization catalyzed by titanium complexes having fluorine-containing phenoxy−imine chelate ligands. J Am Chem Soc. 2003;125:4293–305.

Nishii K, Hagihara H, Ikeda T, Akita M, Shiono T. Stereospecific polymerization of propylene with group 4 ansa-fluorenylamidodimethyl complexes. J Organomet Chem. 2006;691:193–201.

Alimuniar A, Yarmo MA, Rahman MZA, Kohjiya S, Ikeda Y, Yamashita S. Metathesis degradataion of natural rubber. Polym Bull. 1990;23:119–26.

Ouardad S, Deffieux A, Peruch F. Polyisoprene synthesized via cationic polymerization: state of the art. Pure Appl Chem. 2012;84:2065–80.

Jackson C, Chen Y, Mats JW. Size exclusion chromatography with multiple detectors: solution properties of linear chains of varying flexibility in tetrahydrofuran. J Appl Polym Sci. 1996;61:865–74.

Fox TG, Flory PJ. Second-order transition temperatures and related properties of polystyrene. I. Influence of molecular weight. J Appl Phys. 1950;21:581–91.

Shiono T. Living polymerization of olefins with ansa-dimethylsilylene(fluorenyl)(amido)dimethyltitanium-based catalysts. Polym J. 2011;43:331–51.

Furuyama R, Mitani M, Mohri J, Mori R, Tanaka H, Fujita T. Ethylene/higher α-olefin copolymerization behavior of fluorinated bis(phenoxy-imine)titanium complexes with methylalumoxane: synthesis of new polyethylene-based block copolymers. Macromolecules. 2005;38:1546–52.

Acknowledgements

This work was financially supported by JSPS KAKENHI (Grant-in-Aid for Scientific Research (B), Grant Number 21H02002). The generous donation of MAO from Tosoh-Finechem Co. (Japan) is greatly acknowledged. The authors gratefully acknowledge the Natural Science Center for Basic Research and Development (N-BARD-00060), Hiroshima University, for the high-temperature NMR and APCI-MS measurements.

Funding

Open Access funding provided by Hiroshima University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tanaka, R., Shimmei, A., Otsuka, R. et al. Selective synthesis of α-vinyl-ω-vinylidene-oligoisoprene as a macromonomer via ethenolysis of polyisoprene. Polym J 56, 335–342 (2024). https://doi.org/10.1038/s41428-023-00858-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00858-6