Abstract

Amine-cured epoxy resins bearing ester moieties were synthesized, and their properties, hydrolytic degradation behavior, and biomineralization were investigated. Neopentyl glycol diglycidate (NPG) was used as the epoxide and was cured with diethylenetriamine (DETA) and isophoronediamine (IPD) at different ratios. The glass transition temperatures were controlled using the composition of DETA and IPD. The cured materials containing IPD units were tolerant to neutral water but were degraded under acidic and basic conditions. Degradation in the presence of lipase also proceeded in phosphate buffer, while degradation proceeded gradually in the absence of lipase. To demonstrate their potential application as degradable biomedical materials for bone and dental repair, composites containing hydroxyapatite (HA) were prepared by curing NPG and the amines in the presence of HA. Biological bone-like apatite was grown on an NPG-IPD-HA composite by immersion in synthetic biofluid, and the amount of bone-like apatite was greater than that on the glycidyl ether analog.

Similar content being viewed by others

Introduction

Epoxy resins are widely used in coatings, electronic devices, paints, and adhesives due to their chemical and water resistance, stiffness, and tunable physical properties [1,2,3,4,5]. Due to the strain-based high reactivity of epoxides, the curing reaction is fast, which is a major advantage of epoxy resins. In addition, resins with a wide variety of chemical structures and properties can be formed depending on the type of curing agent, providing a wide range of applications.

The majority of epoxy monomers are glycidyl ethers, which are not degradable under typical environmental conditions due to the stability of the ether moieties. As a result, cured epoxy resins tend to persist as microplastics due to their robust chemical structures and physical strength [6,7,8]. The environmental and biological toxicity of epoxides is also a major concern of epoxy resins [9, 10]. In this regard, various hydrolytically degradable epoxy resins have been developed [11,12,13,14,15,16,17,18,19,20]. Glycidyl esters of naturally occurring carboxylic acids are among the most representative of these materials, and successful results have been reported for epoxides based on plant oils [17], itaconic acid [18], furandicarboxylic acid [19, 20], and so on. In addition to these environmental benefits, degradability is advantageous for recycling organic substances from polymers [21, 22] and metals from electronic devices [23, 24].

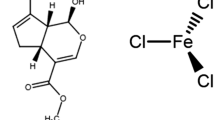

We are developing glycidates, epoxides bearing adjacent ester moieties, as environmentally friendly epoxides [25,26,27,28]. Glycidates are compounds in which the oxymethylene group of a glycidyl ether is replaced by an ester linkage and can be easily synthesized by oxidation of acrylates [25, 29]. We have previously cured a bifunctional glycidate, neopentyl glycol diglycidate (NPG), which exhibits low cytotoxicity [28], with diethylenetriamine (DETA) [26] and cyclic acid anhydrides [27]. Amine curing proceeds under ambient conditions, and the adhesiveness of the cured material of NPG and DETA is greater than that of the glycidyl ether analog. The cured products of NPG and commercial cyclic acid anhydrides also exhibit good adhesiveness and are degradable in basic aqueous media under ambient conditions and in compost at 60 °C. In contrast, the cured products of the analogous glycidyl ether, neopentyl glycol diglycidyl ether (NPGE), do not degrade under identical conditions. Hydrolytic degradation of linear copolycarbonates of monoglycidates and CO2 has also been reported, and the degradation products include biosafe CO2, alcohols, and glyceric acid [30, 31]. The degradability of amine-cured materials is also worth investigating. We herein report the hydrolytic degradation of cured materials of NPG and amines. The cured materials were tolerant to neutral water but were degraded under acidic and basic conditions. Degradation in the presence of lipase also proceeded in phosphate buffer, and degradation proceeded gradually in the absence of lipase. Composites containing hydroxyapatite (HA) were prepared by curing NPG and amines in the presence of HA to demonstrate their potential application as degradable biomedical materials for bone and dental repair; these materials are typically explored using polyesters [32,33,34,35]. Biological apatite was grown on an NPG-amine-HA composite by immersion in synthetic biofluid (SBF), and the amount of bone-like apatite was greater than that on the glycidyl-ether analog. This system has potential to replace biomedical epoxy formulations containing chemicals of health concern, such as bisphenol A diglycidyl ether [36].

Experimental

Materials

Water was purified using an EYELA (Tokyo, Japan) Still Ace SA2100-A water purification machine. NPG was prepared by oxidation of neopentyl glycol diacrylate with NaOCl as previously reported [26]. Neopentyl glycol diacrylate, NPGE, DETA, and isophoronediamine (IPD) were purchased from Tokyo Chemical Industry (Tokyo, Japan). Hydrochloric acid, NaOH solution, 5% NaOCl aq., chloroform, and tetrahydrofuran (THF) were purchased from Kanto Chemical (Tokyo, Japan). Lipase from Candida rugosa was purchased from Sigma‒Aldrich (St. Louis, MO, USA). HA and 0.1 M phosphate buffer (pH = 7.2) were purchased from Wako Pure Chemical (Osaka, Japan). Poly(lactic acid) (PLA) (H100) was obtained from Mitsui Chemicals (Tokyo, Japan). PLA pellets were pressed under reduced pressure for 10 min with a press machine at 170 °C. Then, the temperature was lowered to 130 °C, and the pressed composite was annealed for 1 hour. The heater was turned off, and the mixture was cooled to room temperature to obtain a PLA film. Synthetic biofluid (SBF) was prepared using sodium chloride (Tokyo Chemical Industry), sodium bicarbonate (Kanto Chemical), potassium chloride (Wako Pure Chemical), dipotassium hydrogen phosphate trihydrate (Nakarai Tesque, Kyoto, Japan), magnesium chloride hexahydrate (Wako Pure Chemical), calcium chloride (Wako Chemical), disodium sulfate (Tokyo Chemical Industry), and tris(hydroxymethyl)aminomethane (Wako Pure Chemical) as reported [37]. All the reagents were used as received.

Characterization

Thermogravimetric analysis (TGA) was performed on a Seiko (Tokyo, Japan) TG/DTA6000 (EXSTER6000) instrument (10 °C min−1, N2). Differential scanning calorimetry (DSC) was conducted on a Seiko Instruments (Tokyo, Japan) DSC6200 instrument at a scanning rate of 10 °C/min under N2 flow. Scanning electron microscopy (SEM) was conducted on a JEOL (Tokyo, Japan) JSM-6510A microscope at an accelerating voltage of 10 kV. Energy dispersive X-ray (EDX) analysis was performed with a system consisting of a JEOL JSM6510A scanning electron microscope equipped with a JEOL JED2300 EDX spectrometer operated at an acceleration voltage of 15 kV.

Curing reaction

NPG (366 mg, 1.50 mmol), DETA, and IPD (61.8 (600 μmol) and 0, 30.9 (300 μmol) and 63.8 (375 μmol), 24.7 (239 μmol) and 76.5 (449 μmol), 18.5 (179 μmol) and 89.2 (523 μmol), 12.4 (120 μmol) and 102 (599 μmol), 6.2 (60 μmol) and 115 (675 μmol), and 0 and 128 (751 μmol) mg, respectively) were added to a glass vial containing a magnetic stir bar, and the mixture was stirred with a magnetic stirrer. Then, the mixture was poured into a Teflon mold and cured. Curing in the presence of IPD was conducted at 60 °C for 1 h and then at 100 °C for 1 h. Curing in the absence of IPD was conducted at 25 °C for 1 h and then at 60 °C for 1 h. Composites with HA (183 mg for 30 wt% samples) were also prepared in the same manner.

Hydrolytic degradation

Cured films (w/l/t = 10/20/1 mm) were immersed in aqueous media at 37 °C for 24 h. The degradation time was visually determined as the time when the film collapsed or dissolved.

Biomineralization

Cured films (w/l/t = 5/5/1 mm) were immersed in SBF at 37 °C. SBF was replaced with fresh solution every day. For weight and SEM measurements, the specimen was taken out, washed with water, and dried under reduced pressure.

Results and discussion

Curing reaction and properties of cured products

Previously reported cured products of NPG and DETA (NPG-DETA) are flexible. We accordingly tuned the hardness using rigid IPD. The curing reaction was performed for mixtures of NPG, DETA, and IPD with equimolar amounts of epoxy rings and N–H moieties at 60 °C for 1 h and then at 100 °C for 1 h (Scheme 1, Table 1). Different molar ratios of DETA and IPD were used, and the cured products are abbreviated as NPG-DETAx-IPDy, where x and y represent the molar ratios of the N–H groups. Cured products obtained using NPGE, the glycidyl ether analog of NPG, instead of NPG were prepared for comparison, and the cured products were abbreviated as NPGE-DETAx-IPDy. All the cured products were insoluble in common organic solvents, such as chloroform and tetrahydrofuran. The water resistance of NPG-DETA was insufficient, and the sample immersed in pure water at 25 °C for 24 h lost 10% of its weight. The cured product of NPG and IPD (NPG-IPD) exhibited sufficient water resistance, and weight loss was not detectable. The water resistance of NPG-DETA-IPD and NPGE-DETA-IPD was also high, and the weight loss was less than 3%.

The thermal stability of the cured materials was evaluated via TGA. The 5%-weight-loss temperature (Td5) of the NPG-cured products at approximately 210 °C was lower than that of the NPGE-cured products at approximately 280 °C. The lower thermal resistance of the NPG-cured materials may result from the nucleophilic substitution of the ester linkage by residual primary or secondary amine groups, which results in the elimination of neopentyl glycol.

The glass transition temperature (Tg) is controlled by the composition of DETA and IPD, and cured products obtained with higher IPD ratios exhibit higher Tg values due to the rigidity of the IPD skeleton (Fig. 1). The Tg of the cured products of NPG, which ranged from 5 to 85 °C, was higher than that of the cured products of NPGE, which ranged from 0 to 40 °C.

Hydrolytic degradation of cured products

The hydrolytic degradation of NPG-DETA3-IPD7 and NPGE-DETA3-IPD7 was evaluated in aqueous solutions of HCl and NaOH at 37 °C (Table 2). As mentioned above, the cured materials were stable in pure water and 3 wt% tetraethylammonium chloride solution. NPG-DETA3-IPD7 was degraded and soluble in acidic and basic media, while NPGE-DETA3-IPD7 retained its shape for at least 2 weeks. The degradation of NPG-DETA3-IPD7 is attributed to the hydrolytic cleavage of the ester linkage in the NPG unit since the ether analog NPGE-DETA3-IPD7 was stable. The degradation of NPG-DETA3-IPD7 was faster than that of PLA, a polyester with a similar Tg, indicating that the hydrophilic skeleton assisted hydrolysis. Degradation is faster under basic conditions than under acidic conditions. This tendency is different from that of typical amine-cured epoxy resins, which are tolerant to basic conditions but can be susceptible to acids [38, 39]. The protonation of amine groups increases the hydrophilicity and results in the absorption of water in epoxy-amine-cured polymers. Acid hydrolysis of the ester linkage presumably proceeded with increased water uptake by the hydrophilic ammonium structure. The faster degradation under basic conditions may correlate with the smooth hydrolysis of cured materials of NPG and acid anhydrides under basic conditions, which relies on the formation of hydrophilic carboxylate moieties as degradation progresses [27]. The basic hydrolysis of NPG-DETA3-IPD7 also produces carboxylate moieties that accelerate hydrolysis.

Furthermore, enzymatic degradation was investigated using lipase from Candida rugosa in phosphate buffer (pH = 7.2) at 37 °C. On average, NPG-DETA3-IPD7 was degraded after 11 days, while NPGE-DETA3-IPD7 was not. However, slow degradation also occurred in the absence of lipase in a similar manner as poly(amino esters), which are degraded slowly in PBS or sodium acetate buffer at various pH values [40,41,42]. As a result, the degradation periods differed widely, including shorter periods than those in the presence of lipase. Although the reason is unclear, as in previous studies, degradation in phosphate buffer with lipase likely proceeded by salt-mediated hydrolysis and enzymatic degradation. Anions in phosphate buffer may interact with amine groups on the surface, tilting to form ammonium structures even under neutral conditions to increase hydrophilicity, and these interactions promote the penetration of water in the film to accelerate hydrolysis.

The degradation of NPG-DETA-IPD with different compositions and of NPG-IPD was studied in phosphate buffer containing lipase. NPG-DETA started to degrade within one day even in the absence of lipase and was not tested in detail. Figure 2 shows optical images of NPG-IPD and NPGE-IPD immersed at 37 °C for 7 days. NPG-IPD did not significantly change in the absence of lipase (Fig. 2a) but was whitened by absorption in aqueous media in the presence of lipase (Fig. 2b). After approximately 20 days, the film completely collapsed. In contrast, NPGE-IPD retained its shape even in the presence of lipase (Fig. 2c). The NPG-DETA-IPD films degraded faster than did the NPG-IPD films due to the decrease in the number of hydrophobic IPD units. Films with higher DETA compositions tended to degrade faster due to their lower hydrophobicity, while the degradation time and composition did not match perfectly.

Optical images of (a) NPG-IPD immersed in phosphate buffer without lipase and (b) NPG-IPD and (c) NPGE-IPD immersed in phosphate buffer containing lipase from Candida rugosa ([E] = 140 U/mL) at 37 °C for 7 days. d Average period of degradation of NPG-DETA-IPD in phosphate buffer (pH = 7.2) containing lipase from Candida rugosa ([E] = 140 U/mL) at 37 °C

Biomineralization of cured products containing hydroxyapatite

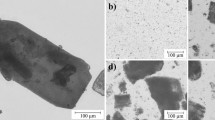

The hydrolytic degradability of these materials implies the potential application of this curing method to biomaterials. As a demonstration of biomedical applications, we evaluated biomineralization on NPG-amine-cured materials and those containing HA, targeting potential applications for dental recalcification and bone regeneration. Curing of NPG and IPD was conducted in the presence of 10 and 30 wt% HA under identical conditions. When curing progressed, HA was homogeneously distributed in the cured composite containing 30 wt% HA, as confirmed by the SEM and EDX images (Fig. 3). In contrast, HA accumulated at the bottom of the cured composite containing 10 wt% HA. This heterogeneity may be attributed to the different viscosities of the monomer mixtures. The monomer mixture containing 30 wt% HA before curing was viscous enough to prevent sedimentation of HA, while that containing 10 wt% HA was not. As a result, HA was gradually sedimented during the curing of the mixture containing 10 wt% HA. We accordingly evaluated the biomineralization behavior of cured composites containing 30 wt% HA.

The epoxy-amine-HA-cured composites and epoxy-amine-cured networked polymers were immersed in SBF at 37 °C for 1, 3, 7, and 14 days. As amines, DETA, DETA/IPD (5/5), and IPD were used. NPG-DETA, NPG-DETA-HA, NPG-DETA5-IPD5, and NPG-DETA5-IPD5-HA were gradually degraded and could not be collected after 14 days. The NPG-IPD, NPG-IPD-HA, and NPGE-based materials retained their shapes during immersion. The weight changes of the dried samples are indicated in Fig. 4. The weights of the shape-retained materials increased by 0.5–5%.

We confirmed the surface morphology of the immersed specimen by SEM to confirm whether the weight increase originated from the formation of bone-like apatite on the surface. We could not observe grains ascribable to bone-like apatite on the surfaces of NPG-IPD-HA and NPG-IPD immersed in SBF for 1 and 3 days (Figs. 5 and 6a, b). After 7 days of immersion, grains became observable on the surface of NPG-IPD-HA but were not detectable on the surface of NPG-IPD (Figs. 4c and 5c). The grains on NPG-IPD-HA are clearer in the SEM image of NPG-IPD-HA immersed in SBF for 14 days, and the deposited area matches the EDX map of Ca (Fig. 5d, e), supporting that the grains observed are bone-like apatite deposited from SBF. After NPG-IPD was immersed for 14 days, clear grains were not observed. This difference indicates that HA promoted the initial nucleation of biological apatite on the surface of the composite.

The amount of bone-like apatite formed on NPGE-IPD-HA was lower than that on NPG-IPD-HA (Fig. 7a). The more efficient formation of bone-like apatite on NPG-IPD-HA probably results from the greater polarity of the ester moieties than of the ether moieties. However, bone-like apatite formation was clearly observed on NPGE-DETA-HA (Fig. 7b). Plausible factors are the higher stickiness of NPGE-DETA due to its lower Tg, which is suitable for adhesion, and the presence of unreacted secondary amine moieties electrostatically adsorbing ions in SBF [43] to promote the nucleation of biological apatite.

Conclusion

Hydrolytically degradable epoxy–amine cured resins bearing ester moieties were developed by curing NPG, a bifunctional glycidate, with different ratios of DETA and IPD. The hydrolytic degradability and glass transition temperatures were controlled by the composition of DETA and IPD. Composites containing HA were prepared by curing NPG and amines in the presence of HA. Biological apatite was grown on a composite of NPG-amine-HA composite by immersion in SBF, and the amount of bone-like apatite was greater than that on the glycidyl ether analog. Biomineralization ability, degradability, and simple curing processes are advantages for the application of bone regeneration and dental recalcination materials. Other potential applications include dismantlable adhesives and degradable fiber-reinforced plastics for facile recycling of adhered materials and fibers, respectively. The balance of properties, acceleration of curing, and selection of biosafe monomers and degradation products are the next ongoing challenges for practical applications.

References

Ochi M. Structure and properties of functional epoxy resins. J Adhes Soc Jpn. 2003;39:432–7.

Vidil T, Tournilhac F, Musso S, Robisson A, Leibler L. Control of reactions and network structures of epoxy thermosets. Prog Polym Sci. 2016;62:126–79.

Rahman MM, Islam MA. Application of epoxy resins in building materials: progress and prospects. Polym Bull. 2022;79:1949–75.

Mi XQ, Liang N, Xu HF, We J, Jiang Y, Nie B, Zhang DH. Toughness and its mechanisms in epoxy resins. Prog Mater Sci. 2022;130:100977.

Shundo A, Yamamoto S, Tanaka K. Network formation and physical properties of epoxy resins for future practical applications. JACS Au. 2022;2:1522–42.

Mintenig SM, Löder MGJ, Primpke S, Gerdts G. Low numbers of microplastics detected in drinking water from ground water sources. Sci Total Environ. 2019;648:631–5.

Liu K, Wang XH, Fang T, Xu P, Zhu LX, Li DJ. Source and potential risk assessment of suspended atmospheric microplastics in Shanghai. Sci Total Environ. 2019;675:462–71.

Amorim MJB, Scott-Fordsmand JJ. Plastic pollution — A case study with Enchytraeus crypticus — From micro-to nanoplastics. Environ Pollut 2021;271:116363.

Gardiner TH, Waechter JM Jr, Wiedow MA, Solomon WT. Glycidyloxy compounds used in epoxy resin systems: A toxicology review. Regul Toxic Pharmac. 1992;15:S1–S77.

González MP, Helguera AM, Ruiz RM, Fárdales JRG. A topological sub-structural approach of the mutagenic activity in dental monomers. 1. Aromatic epoxides. Polymer. 2004;45:2773–9.

Auvergne R, Caillol S, David G, Boutevin B, Pascault J. Biobased thermosetting epoxy: present and future. Chem Rev. 2014;114:1082–1115.

Mashouf Roudsari G, Mohanty AK, Misra M. Green approaches to engineer tough biobased epoxies: a review. ACS Sustain Chem Eng. 2017;5:9528–41.

Wan J, Zhao J, Zhang X, Fan H, Zhang J, Hu D, Jin P, Wang DY. Epoxy thermosets and materials derived from bio-based monomeric phenols: transformations and performances. Prog Polym Sci. 2020;108:101287.

Feng Z, Nikafshar S, Hegg EL, Nejad M. Biobased divanillin as a precursor for formulating biobased epoxy resin. ACS Sustain Chem Eng. 2020;8:9095–103.

Shen MJ, Robertson ML. Degradation behavior of biobased epoxy resins in mild acidic media. ACS Sustain Chem Eng. 2021;9:438–47.

Yokoyama Y, Yasui T, Takeda A, Ogino K, Kanehashi S. Novel bio-based flexible bisphenol epoxy resin derived from cashew nut shell liquid. Polym J. 2023;55:859–67.

Silau H, Garcia AG, Woodley JM, Dam-Johansen K, Daugaard AE. Bio-based epoxy binders from lignin derivatized with epoxidized rapeseed fatty acids in bimodal coating systems. ACS Appl Polym Mater. 2022;4:444–51.

Ma S, Liu Z, Jiang Y, Tang Z, Zhang C, Zhu J. Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem. 2013;15:245–54.

Deng J, Liu X, Li C, Jiang Y, Zhu J. Synthesis and properties of a bio-based epoxy resin from 2,5-furandicarboxylic acid (FDCA). RSC Adv. 2015;5:15930–9.

Miao JT, Yuan L, Guan Q, Liang G, Gu A. Biobased heat resistant epoxy resin with extremely high biomass content from 2,5-furandicarboxylic acid and eugenol. ACS Sustain Chem Eng. 2017;5:7003–11.

Wang J, Li YC, Song JF, He MY, Song JJ, Xia K. Recycling of acrylonitrile-butadiene-styrene (ABS) copolymers from waste electrical and electronic equipment (WEEE), through using an epoxy-based chain extender. Polym Degrad Stabil. 2015;112:167–74.

Turel T, Daglar O, Eisenreich F, Tomovic Z. Epoxy thermosets designed for chemical recycling. Chem Asian J. 2023;18:e202300373.

Ning C, Lin CSK, Hui DCW, McKay G. Waste printed circuit board (PCB) recycling techniques. Top Curr Chem. 2017;375:43.

Hao J, Wang Y, We Y, Guo F. Metal recovery from waste printed circuit boards: a review for current status and perspectives. Res Conserv Recycl. 2020;157:104787.

Ochiai B, Hirano T. Facile Synthesis of glycidates via oxidation of acrylates with aqueous solution of NaOCl in the presence of ammonium salts. Heterocycles. 2014;89:487–93.

Ochiai B, Soegawa K. Glycidate as a high-strength epoxy adhesive curable with amine under ambient conditions. Polymers. 2022;14:957.

Ochiai B, Yashima M, Soegawa K, Matsumura Y. Biodegradable epoxy thermosetting system with high adhesiveness based on glycidate-acid anhydride curing. ACS Macro Lett. 2023;12:54–58.

Ochiai B, Yano S, Soegawa K. Novel polyfunctional glycidic ester compound and production method thereof, and polymer prepared using the same. JP-Patent. 2015, 2015-214497A.

Moriwaki Y, Akaishi R. Production of α,β-epoxycarboxylic acid derivative. JP-Patent. 1993, H5-39277.

Zhang H, Lin X, Chin S, Grinstaff MW. Synthesis and characterization of poly(glyceric acid carbonate): a degradable analogue of poly(acrylic acid). J Am Chem Soc. 2015;137:12660–6.

Beharaj A, Ekladious I, Grinstaff MW. Poly(alkyl glycidate carbonate)s as degradable pressure-sensitive adhesives. Angew Chem Int Ed. 2019;58:1407–11.

Sheikh Z, Najeeb S, Khurshid Z, Verma V, Rashid H, Glogauer M. Biodegradable materials for bone repair and tissue engineering applications. Materials. 2015;8:5744–94.

Gigli M, Fabbri M, Lotti N, Gamberini R, Rimini B, Munari A. Poly(butylene succinate)-based polyesters for biomedical applications: A review. Eur Polym J. 2016;75:431–60.

Ng HM, Bee ST, Sin LT, Ratnam CT, Rahmat AR. Hydroxyapatite for poly(α-hydroxy esters) biocomposites applications. Polym Rev. 2019;59:187–239.

Fu Z, Cui J, Zhao B, Shen SGF, Lin K. An overview of polyester/hydroxyapatite composites for bone tissue repairing. J Orthop Transl. 2021;28:118–30.

Abdulrazzaq B, Al-Bakhsh J, Shafiei F, Hashemian A, Shekofteh K, Bolhari B, Behroozibakhsh M. In-vitro bioactivity evaluation and physical properties of an epoxy-based dental sealer reinforced with synthesized fluorine-substituted hydroxyapatite, hydroxyapatite and bioactive glass nanofillers. Bioact Mater. 2019;4:322–33.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials. 2006;27:2907–15.

Wegmann A. Chemical resistance of waterborne epoxy/amine coatings. Prog Org Coat. 1997;32:231–9.

Gorovin VA, Il’in AB. Composite protective coatings. Resistance to acid penetration of coatings based on epoxy resins. Int J Corros Scale Inhib. 2020;9:1530–49.

Lynn DM, Langer R. Degradable poly(β-amino esters): synthesis, characterization, and self-assembly with plasmid DNA. J Am Chem Soc. 2000;122:10761–10768.

Zhong Z, Song Y, Engbersen JFJ, Lok MC, Hennink WE, Feijen J. A versatile family of degradable non-viral gene carriers based on hyperbranched poly(ester amine)s. J Controlled Rel. 2005;109:317–29.

Zhang J, Fredin NJ, Janz JF, Sun B, Lynn DM. Structure/property relationships in erodible multilayered films: influence of polycation structure on erosion profiles and the release of anionic polyelectrolytes. Langmuir. 2006;22:239–45.

Pattanayak DK, Yamaguchi S, Matsushita T, Nakamura T, Kokubo T. Apatite-forming ability of titanium in terms of pH of the exposed solution. J R Soc Inter. 2012;9:2145–55.

Acknowledgements

We are thankful for the financial support from JSPS KAKENHI (grant number JP19K22212), the Adaptable and Seamless Technology Transfer Program through Target-driven R&D (A-STEP) from Japan Science and Technology Agency (JST) (grant number AS2621327M, and Nagase ChemteX Co., Inc.), and the kind advice from Mr. Tetsuya Hosomi of Nagase ChemteX Co., Inc.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ochiai, B., Nakazawa, Y., Matsumura, Y. et al. Hydrolytic degradation and biomineralization of amine-cured epoxy resin based on glycidate. Polym J 56, 409–417 (2024). https://doi.org/10.1038/s41428-023-00880-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00880-8