Abstract

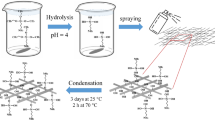

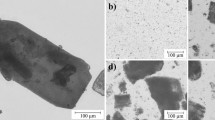

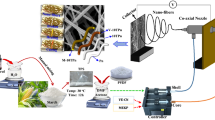

In this study, the preparation and characterization of unsaturated polyester resin (UPR) composites reinforced with abaca fibers modified using radiation-induced graft polymerization are investigated. The aim is to assess the influences of these modified abaca fibers as reinforcement materials on the thermal stability, moisture resistance, and mechanical properties of the composites. The results demonstrate significant enhancements in the tensile and flexural strengths of the prepared composites relative to those reinforced with untreated fibers, yielding minimum increases of 23% in tensile strength and 59% in flexural strength. The most substantial improvement is achieved with abaca fibers modified through the reversible addition−fragmentation chain-transfer–mediated grafting mechanism. In addition, short, grafted chains on abaca fibers produce the greatest enhancement in mechanical strength. The modified composites exhibit improved thermal stability and moisture resistance. These enhancements can be attributed to the improved interfacial adhesion between the modified abaca fibers and the UPR matrix, as confirmed by scanning electron microscope analysis. Overall, these findings highlight the potential of this approach as a surface modification technique for enhancing the applicability of natural fibers in the composite industry.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Abobo MID, Rodriguez LD, Salvador SD, Siy HC, Penaloza DP Jr. Effect of organoclay reinforcement on the mechanical and thermal properties of unsaturated polyester resin composites. Epa J Silic Based Compos Mater. 2021;73:63–67. https://doi.org/10.14382/epitoanyag-jsbcm.2021.10.

Penczek P, Czub P, Pielichowski J. Unsaturated polyester resins: chemistry and technology. Adv Polym Sci. 2005; 1–95. https://doi.org/10.1007/b136243.

Aziz SH, Ansell MP, Clarke SJ, Panteny SR. Modified polyester resins for natural fibre composites. Compos Sci Technol. 2005;65:525–35. https://doi.org/10.1016/j.compscitech.2004.08.005.

John MJ, Anandjiwala RD. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym Compos. 2008;29:187–207. https://doi.org/10.1002/pc.20461.

Thomas S, Chirayil CJ, Hosur M. Unsaturated polyester resins: fundamentals, design, fabrication, and applications. Amsterdam: Elsevier; 2019. https://doi.org/10.1016/C2017-0-04622-0.

Ku H, Wang H, Pattarachaiyakoop N, Trada M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos Part B Eng. 2011;42:856–73. https://doi.org/10.1016/j.compositesb.2011.01.010.

Li X, Tabil LG, Panigrahi S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ. 2007;15:25–33. https://doi.org/10.1007/s10924-006-0042-3.

Faruk O, Bledzki AK, Fink H-P, Sain M. Biocomposites reinforced with natural fibers: 2000-2010. Prog Polym Sci. 2012;37:1552–96. https://doi.org/10.1016/j.progpolymsci.2012.04.003.

Suresh G, Jayakumari LS, Suresh G, Jayakumari LS. Evaluating the mechanical properties of E-Glass fiber/carbon fiber reinforced interpenetrating polymer networks. Polímeros. 2015;25:49–57. https://doi.org/10.1590/0104-1428.1650.

Raghavendran VK, Drzal LT. Fiber-matrix interfacial adhesion improvement in carbon fiber-bisphenol-a polycarbonate composites by polymer grafting. J Adhes. 2002;78:895–922. https://doi.org/10.1080/00218460290010476.

Li M, Pu Y, Thomas VM, Yoo CG, Ozcan S, Deng Y, et al. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos Part B Eng. 2020;200:108254. https://doi.org/10.1016/j.compositesb.2020.108254.

Barba BJD, Madrid JF, Penaloza Jr DP. A review of abaca fiber-reinforced polymer composites: different modes of preparation and their applications. J Chil Chem Soc. 2020;65:4919–24. https://doi.org/10.4067/s0717-97072020000204919.

Célino A, Fréour S, Jacquemin F, Casari P. The hygroscopic behavior of plant fibers: a review. Front Chem. 2013;1:43 https://doi.org/10.3389/fchem.2013.00043.

Joshi S, Drzal L, Mohanty A, Arora S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos Part A Appl Sci Manuf. 2004;35:371–6. https://doi.org/10.1016/j.compositesa.2003.09.016.

Shahri W, Tahir I, Ahad B. Abaca fiber: A renewable bio-resource for industrial uses and other applications. In: Hakeem, K., Jawaid, M., Rashid, U. (eds) Biomass and Bioenergy. Switzerland: Springer. 2014; 47–61. https://doi.org/10.1007/978-3-319-07641-6_3.

Delicano JA. A review on abaca fiber reinforced composites. Compos Interfaces. 2018;25:1039–66. https://doi.org/10.1080/09276440.2018.1464856.

Philippine Fiber Industry Development Authority. Improvement of Fiber Extraction and Identification of Higher Yielding Varieties. Activities in the Philippines. 2009. https://www.unido.org/fileadmin/import/48269_Activities_in_Philippines.pdf Accessed 28 June 2019.

Kaith BS, Singha AS, Kalia S. Grafting MMA onto flax under the influence of microwave radiation and the use of flax-g-poly (MMA) in preparing PF composites. Autex Res J. 2007;7:119–29.

Stannett VT. Radiation grafting—state-of-the-art. Int J Radiat Appl Instrum Part C Radiat Phys Chem. 1990;35:82–87. https://doi.org/10.1016/1359-0197(90)90062-M.

Barba BJD, Peñaloza DP, Seko N, Madrid JF. RAFT-mediated radiation grafting on natural fibers in aqueous emulsion. Mater Proc. 2021;7:4. https://doi.org/10.3390/IOCPS2021-11243.

Barsbay M, Güven O, Stenzel MH, Davis TP, Barner-Kowollik C, Barner L. Verification of controlled grafting of styrene from cellulose via radiation-induced RAFT polymerization. Macromolecules. 2007;40:7140–7. https://doi.org/10.1021/ma070825u.

Madrid JF, Barsbay M, Abad L, Güven O. Grafting of N, N-dimethylaminoethyl methacrylate from PE/PP nonwoven fabric via radiation-induced RAFT polymerization and quaternization of the grafts. Radiat Phys Chem. 2016;124:145–54. https://doi.org/10.1016/j.radphyschem.2016.01.004.

Madrid JF, Ueki Y, Abad LV, Yamanobe T, Seko N. Enhanced amination and adsorption performance of functional copolymer synthesized via RAFT-mediated radiation grafting in emulsion. J Polym Res. 2018;25:193 https://doi.org/10.1007/s10965-018-1585-4.

Barba BJD, Peñaloza DP, Seko N, Madrid JF. Radiation-induced controlled grafting from lignocellulosic fiber towards compatibilization for composite reinforcement. J Nat Fibers. 2022;19:14055–66. https://doi.org/10.1080/15440478.2022.2114980.

Madrid JF, Nuesca GM, Abad LV. Gamma radiation-induced grafting of glycidyl methacrylate (GMA) onto water hyacinth fibers. Radiat Phys Chem. 2013;85:182–8. https://doi.org/10.1016/j.radphyschem.2012.10.006.

Madrid JF, Cabalar PJE, Abad LV. Radiation-induced graft polymerization of acrylic acid and glycidyl methacrylate onto abaca/polyester nonwoven fabric. J Nat Fibers. 2018;15:625–38. https://doi.org/10.1080/15440478.2017.1349713.

Paglicawan MA, Kim BS, Basilia BA, Emolaga CS, Marasigan DD, Maglalang PEC. Plasma-treated abaca fabric/unsaturated polyester composite fabricated by vacuum-assisted resin transfer molding. Int J Precis Eng Manuf Technol. 2014;1:241–6. https://doi.org/10.1007/s40684-014-0030-3.

Leong YW, Thitithanasarn S, Yamada K, Hamada H. Compression and injection molding techniques for natural fiber composites. Nat Fibre Compos. 2014:216–32. https://doi.org/10.1533/9780857099228.2.216.

Muzammil EM, Khan A, Stuparu MC. Post-polymerization modification reactions of poly (glycidyl methacrylate). RSC Adv. 2017;7:55874–84. https://doi.org/10.1039/C7RA11093F.

Paglicawan MA, Basilia BA, Kim BS. Water uptake and tensile properties of plasma treated abaca fiber reinforced epoxy composite. Compos Res. 2013;26:165–9. https://doi.org/10.7234/composres.2013.26.3.165.

Michalek L, Mundsinger K, Barner-Kowollik C, Barner L. The long and the short of polymer grafting. Polym Chem. 2019;10:54–59. https://doi.org/10.1039/C8PY01470A.

Rodrígues BS, García RM, Leão RM, Amico SC, Luz SM. Hemicellulose removal in Curaua (Ananas erectifolius) fibers for polyester composites. Nova Sientia. 2018;10:154–72. https://doi.org/10.21640/ns.v10i21.1509.

Abdul Khalil HPS, Suraya NL, Atiqah N, Jawaid M, Hassan A. Mechanical and thermal properties of chemical treated kenaf fibres reinforced polyester composites. J Compos Mater. 2013;47:3343–50. https://doi.org/10.1177/0021998312465026.

Fuqua MA, Huo S, Ulven CA. Natural fiber reinforced composites. Polym Rev. 2012;52:259–320. https://doi.org/10.1080/15583724.2012.705409.

Nerenz BA, Fuqua MA, Chevali VS, Ulven CA. Processing and characterization of a polypropylene biocomposite compounded with maleated and acrylated compatibilizers. Int J Polym Sci. 2012;2012:472078. https://doi.org/10.1155/2012/472078.

Kale A, Raghu N, Natu HP, Aggarwal P, Chauhan S. Effect of grafting yield and molecular weight of m-TMI-grafted-PP on the mechanical properties of wood fiber filled polypropylene composites. J Appl Polym Sci. 2016;133. https://doi.org/10.1002/app.44196.

McCartney LN. New theoretical model of stress transfer between fibre and matrix in a uniaxially fibre-reinforced composite. Proc R Soc A Math Phys Eng Sci. 1989;425:215–44. https://doi.org/10.1098/rspa.1989.0104.

Acknowledgements

The authors acknowledge the financial support given by the Department of Science and Technology–Science Education Institute (DOST–SEI), which sponsored the graduate scholarship and fellowship grant of Barba as part of their Human Resource Development Program. This work was partially supported by JSPS KAKENHI (Grant No. JP17K05956). The authors acknowledge the contributions of the Environment Polymer Group of QST-TARRI in providing assistance and facilities for conducting the experiments.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barba, B.J.D., Seko, N., Madrid, J.F. et al. Modified abaca fiber prepared by radiation-induced graft polymerization as a reinforcement for unsaturated polyester resin composites. Polym J 56, 97–105 (2024). https://doi.org/10.1038/s41428-023-00851-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00851-z